Home inspectors are often asked to render opinions on other professionals work. Many times we are challenged by licensed professionals, such as engineers, architects, and contractors, who feel differently about a problem.

Who is right?

Remember professional inspectors offer an OPINION of the condition of a building. This should be an informed opinion based upon knowledge and experience; but it is OUR opinion and not someone else’s. Sought after home inspectors are often in disagreement with others and we need to be firm in our conclusions if we are to best serve our clients.

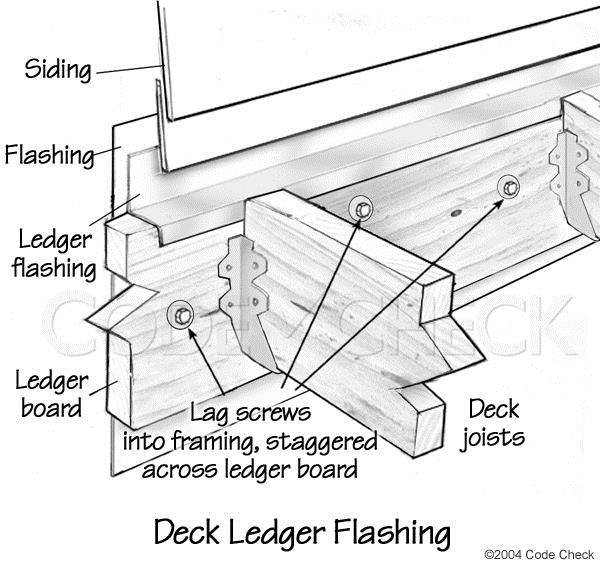

Recently, I inspected a 7 year old commercial building that was in bank foreclosure. My first and primary concern was moisture intrusion. I began my analysis on the exterior of this concrete block and brick structure. Soon, I found a number of details that concerned me:

- The roof valley drainage was restricted by a decorative facade

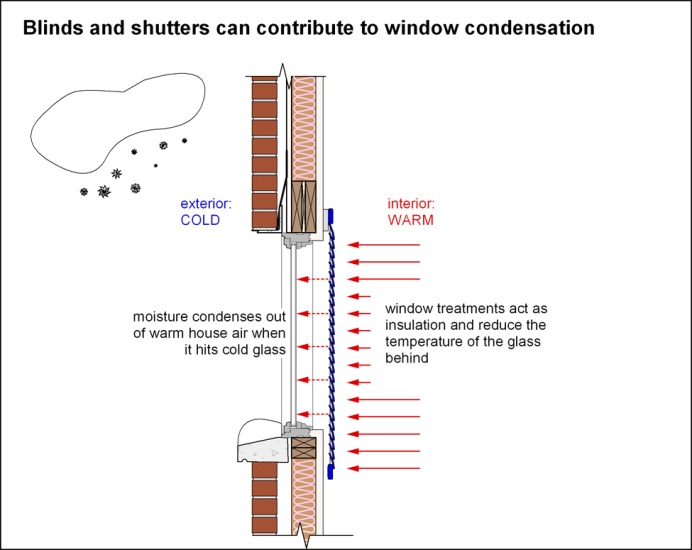

- No rubber gaskets were on the nails of the roof to wall metal flashing

- Many brick wall locations requiring weep ropes had none or were mortared over

- The window and door steel lintels were painted but had already rusted

When I went inside I observed:

- Water stains on the concrete floors and plaster ceilings

- Water stains on the window sill frames

Shortly after relating these concerns to my client, I received an engineering report on the building. Evidently, the building had already been in litigation and this had not been disclosed to my client. The engineering report confirmed many of my findings.

The engineering firm designed a very thorough and costly solution to this complex problem. It included all new window, door, and roof flashing, as well as adding brick weep ropes. I recommended that these detailed repairs be completed to resolve the issue and keep the water out of the building. However, the engineer also said that this problem could be managed by water sealing the exterior bricks. In the end, the bank determined that sealing the face of the bricks was sufficient to correct the problem and resell the building.

My client looked to me to advise them on this matter. Was I OK that this moisture problem had been resolved with a thin coat of brick water sealer?

How do you feel about it?

Email me at doug@citiesinspection.com with your opinion and I will reply with mine.

![]() Doug Hastings

Doug Hastings

MN Home Inspector, Minneapolis & St. Paul

ASHI Certified Inspector, ACI

Kaplan University, Home Inspection Lead Instructor